|

Products

|

||||||||||||||||||||||||||||||||||

| POLYPROPYLENE BAGS | ||||||||||||||||||||||||||||||||||

|

The polypropylene

woven bags (PP bags) are tubular woven made - on circular looms, with

no lateral sewing. The product is designed for packing commodities ranging

from 10 kg to 50 kg, such as sugar, rice, flour, beans, seeds, cereals,

animal feed, salt, fertilizers, chemicals, etc. The PP woven bags can

be flat or with gusset, being suitable to be palletized. |

||||||||||||||||||||||||||||||||||

|

Construction

|

|

|||||||||||||||||||||||||||||||||

|

We can produce

for you all sizes between 350 to 800 mm width and 600 to 1250 mm length; The UV stabilizer ensures the prolonged resistance in the sunshine and the masterbatches can give real nice color to your bags, offering multiple choices: red, green, yellow, blue, black, etc. With our professional

printing press we can custom print the bags to your specifications in

maximum 6 durable colors on both sides, using water-based, lead-free

inks, offering more attractive appearance. |

||||||||||||||||||||||||||||||||||

| POLYETHYLENE WOVEN BAGS AND POLYETHYLENE LINERS |

Order Form |

|||||||||||||||||||||||||||||||||

|

Besides the PP woven bags, Living Plastic Industry S.A. can produce also polyethylene woven bags (PE woven bags) and polyethylene (PE) liners for PP bags. LINER

BAGS: |

||||||||||||||||||||||||||||||||||

|

Construction

|

|

|||||||||||||||||||||||||||||||||

| CEMENT BAGS | ||||||||||||||||||||||||||||||||||

|

The cement bags offered by our company are made of PP woven laminated material (no paper!), provided with gusset and valve. They are specially designed for the automatic or manual packing of 50 kg of cement and 25 kg of lime, but, based on request, they can be tailored for other chemical products. They

are the best alternative to the paper bags, the advantages which they

bring to the end-user being obvious: |

||||||||||||||||||||||||||||||||||

|

Construction

|

|

|||||||||||||||||||||||||||||||||

|

- the bag can be re-used after the cement consumption; |

||||||||||||||||||||||||||||||||||

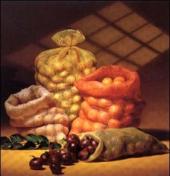

| RASCHEL BAGS | ||||||||||||||||||||||||||||||||||

|

These are our vegetable bags, suitable for potato,

cucubers, carrots,

onion, etc;

We can offer you two standard sizes (for 5 to 25 kg); Our bags have no limit when it comes to colors: red, yellow, green, purple, white, orange, etc. Three more words: RESISTANCE, NICE ASPECT, GOOD PRICE. |

||||||||||||||||||||||||||||||||||

|

Construction

|

|

|||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||

| ZIPPER BAGS | ||||||||||||||||||||||||||||||||||

|

Made with a closing zipper at the top of the bags;

Suitable for drugstores, frozen stuff, food, chemical, clothing industry; Our offer includes numerous sizes (40x60mm to 340x450mm); The printing offer includes printings in 1 to 6 colors, white printing for hand writing, plain zipper bags. |

||||||||||||||||||||||||||||||||||

|

Construction

|

|

|||||||||||||||||||||||||||||||||

| Perfect

transparency: Your product can be seen very well trough our

bag, without affecting its image. No leaking: From now on, your powders or very small objects are safely deposited here. Have no worry, you won’t lose them again! No dust: It’s important for you to keep your products away from dust or other powder’ s influence? This is your bags. Zip it, and you will have a pure product. No unpleasant smells: The zipper bag is ideal for keeping your product away from the influence of other smells. It maintains the initial smell and taste of your product: perfect for food products, no matter their consistence. It keeps your products always fresh; Easy to handle: Just tear the zipper and your product is safely kept a long time. Click here to see how to open and close. For sensitive products, we can add to your zipper bags a ventilation system, using a punching system for small holes. Carrying system: Nothing better than to have a resistant and portable zipper bag! The zipper bags can be used in a large field of domains. Here is what we propose: Food industry: frozen stuff, powders (flour, sugar, salt, spices), bread, sweets, cereals, etc. Pharmaceutical industry: medicines (pills, phials), compresses, bandages, medical teas, etc. Stationary: paper clips, pens, markers, paper, notebooks, books, envelopes, documents, etc. Electronic components and spare parts for different products; Housekeeping: you can keep your, books, jewelry, powders , cosmetics, money, etc. You can always bring new utilities to the ones already presented, We are counting on your productive imagination for this. If you have any suggestions, don’t hesitate to call us! |

||||||||||||||||||||||||||||||||||

| PP STRAPPING BAND |

Order Form |

|||||||||||||||||||||||||||||||||

|

PP strapping is used to secure, to close,

to unitise or to strengthen packages or to reduce package volumes; it is

applied under tension by hand tools or automatic machines. PP strapping

is produced in extrusion lines from polypropylene resin and provides for

high-strength applications. PP strapping, on account of its resistance

to corrosion, its superior elongation, improved safety features (being

less dangerous when the strapping is removed from the load) and lower

weight provides benefits which cannot be achieved by steel strapping.

Provides considerable advantage for many applications such as packing, palletizing, bundling, utilizing. It's excellent elongation and stiffness satisfy the variety of customer's needs. |

||||||||||||||||||||||||||||||||||

|

Technical

Data:

|

|

|||||||||||||||||||||||||||||||||

| SHOPPING BAGS |

Order Form |

|||||||||||||||||||||||||||||||||

|

Plain, white or printed shopping bags, T-shirt type, different sizes.

T-shirt bags with a special tab for easy "one at a time" tear-off dispensing. Large side handles makes these the most convenient bags for carrying large or heavy packages. |

||||||||||||||||||||||||||||||||||

|

Technical

Data:

|

|

|||||||||||||||||||||||||||||||||

| WORKSHOP CYLINDERS (Rotogravure cylinders) |

Order Form |

|||||||||||||||||||||||||||||||||

|

The

printing cylinders or plates are prepared from positives of pages on

which neither text nor illustrations are screened. The photosensitive

substance necessary for carrying out the photoengraving operation,

carbon tissue, is separately packaged to permit it to be treated before

being affixed to the metal. Carbon tissue is paper, in sheets or on

rolls, coated with a layer of gelatin. This layer is sensitized before

use by being plunged into a solution of potassium bichromate. The carbon

tissue is first exposed to intense light through a glass plate bearing a

transparent screen on an opaque background and then exposed a second

time through a positive of the pages. During these two exposures the

gelatin is hardened by the light, completely in the white and screened

areas, more or less deeply in the halftones of the photographic

illustrations, and not at all in the areas covered by text and lines.

The carbon tissue is then applied to the copper surface of the cylinder (or plate). The tissue is then peeled off, leaving the gelatin film fused with the metal. The cylinder (or plate) is plunged into a warm-water bath, which dissolves the gelatin in inverse proportion to the degree to which it was hardened: totally in areas where it received no light like the text and line drawings, more or less deeply in the halftone photographic illustrations, and not at all in the screened areas. The etching of the copper is begun by sprinkling it with a solution of ferric chloride, which attacks the metal in the areas where the gelatin is totally dissolved and bites into it more or less deeply depending on the thickness of the surviving gelatin that it must penetrate. After being etched, the printing surface can be reinforced by chromium plating. Improvements on this classic method of preparing the rotogravure plate are continually being made. The carbon tissue may be replaced with silver emulsions on a plastic base; a direct copy without carbon tissue may be made by dusting the cylinder with a photosensitive substance and projecting the image on the surface of the cylinder by optical means or by electronic engraving. Plates for rotogravure are made of solid copper. Rotogravure cylinders consist of a steel mandrel on which a layer of copper has been deposited by electroplating. After printing, the etching is removed by grinding and a thin film of copper deposited to restore the cylinder to its original diameter. Restoration is simplified if the film can be prevented from adhering to the cylinder so that it can be ripped off after printing. This can be done by coating the surface of the cylinder with a copper-mercury amalgam before electroplating. After plating, the new copper film is then polished. Some electroplating baths produce a shiny copper finish, dispensing with the polishing operation. |

||||||||||||||||||||||||||||||||||

|

Technical

Data:

|

|

|||||||||||||||||||||||||||||||||

|

Copyright © 2000 Living Plastic Industry S.A. All rights reserved. Send comments about this web site to webmaster. |

||||||||||||||||||||||||||||||||||